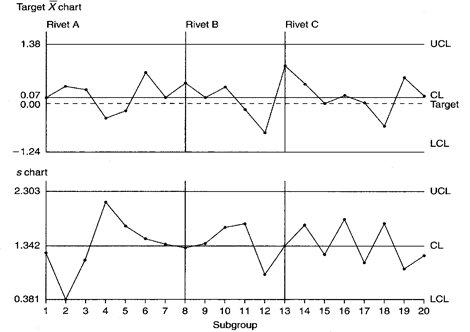

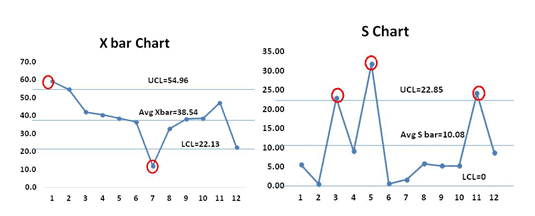

There will also be a step in the centerline for the s chart, wherever there is a change in subgroup size. Subgroups can also be very large, as in administration databases.įor charts with varying subgroup sizes, the control limits step up and down, being wider for the smaller subgroups. The subgroup size may vary, and can be as low as 2 or 3. A subgroup is a set of measurements that are obtained under similar conditions or during the same time period. Each of these plots statistics that are calculated from. The chart centerlines are x-double-bar and s-bar.ĭata are from observations that have been aggregated into subgroups that are as homogeneous as possible (elements within the subgroup are as much alike as possible). The control charts for continuous data with subgroups can be made using Xbar-R charts. These two variables are usually plotted over time. Ĭlick Exclude Subgroups.The Xbar and s chart is a pair of independent control charts, one on the averages of each subgroup (xbar values) and one on the spread (standard deviation) between the measurements within each subgroup.Show Highlighted Points for Excluded Subgroups. To calculate the control limits excluding subgroups 21 to 25, click.The control limits here were calculated including subgroups 21 to 25 which have a known assignable cause. The resulting X-bar & R charts are displayed:.Select Shots 1-3, click Numeric Data Variables (Y) >.Click on Sheet 1 (or press F4 to activate last worksheet). X-bar control limits are based on either range or sigma, depending on which chart it is paired with.The standard chart for variables data, X. This control chart is used to check whether the measurement values deviate from the average (Xbar) and the range. An X-bar and R (range) chart is a pair of control charts used with processes that have a subgroup size of two or more. X-Bar & R Charts – Exclude Subgroups After creating a control chart, you can specify subgroups (or rows) to exclude by using the Types of Control Charts Xbar-R control chart. If the process was stable, the actual performance indices Pp and Ppk would be closer to the Cp and Cpk values. X-Bar & R – Proc Cap sheet for the Process Capability report: Note the difference between Pp and Cp Ppk and Cpk. The resulting dialog box settings are shown:.Shots 1-3, click Numeric Data Variables (Y) >. Sheet 1 (or press F4 to activate last worksheet). Now we will look at Process Capability Indices for this process.Click on the data point to add the comment. To add a comment to a data point, select.Test 1 to 4 settings will be applied to Attribute Charts.) (Note that these defaults will apply to Individuals and X-bar charts. SigmaXL > Control Charts > “Tests for Special Causes” Defaults to run selected tests for special causes. Test 2 can be set to 7, 8, or 9 points in a row on same side of CL. The tests for special causes can have defaults set to apply any or all of Tests 1-8.Note that the Range chart is in-control even though the X-Bar chart is out-of-control: The use of tests for special causes gave us an early warning of this at observation number 22. In this case, the assignable cause was a change of rubber band requiring a reset of the pull back angle. The process must be stopped, and the Out-of-Control Action Plan must be followed to determine and fix the root cause. Tests for Special Causes report clearly shows that this process is now out of control with an unstable mean. Tests for Special Causes report gives us more detail on the recent instability: The X-bar chart and Recalculated when a deliberate process change or improvement is

Once control limits are established, they should only be Note that the Add Data button does NOT recalculate the control SigmaXL Chart Tools > Add Data to this Control Chart as shown. Once the R chart exhibits control (such as the above chart), then an out of control condition. The UCL and LCL on the Xbar chart are calculated with inputs related to process centering and spread (variation). This chart must exhibit control in order to make conclusions on the Xbar chart.

Xbar control chart software#

To add the additional data to this chart, click Then, taking into account the SPC, the analysis of the data collected is presented making use of the X-bar and R control chart through the software Minitab. The R chart is the control chart for the subgroup ranges. Subgroups 21 to 25 were added afterwards.

Shot 2, Shot 3, click Numeric Data Variables (Y) > select Select B2:F22 here, we will only use the first 20 subgroups to determine the control limits.The Lower Specification Limit (LSL) is 92 inches. The Upper Specification Limit (USL) is 108 inches. Open the file Catapult Data – Xbar Control Charts.xlsx.

0 kommentar(er)

0 kommentar(er)